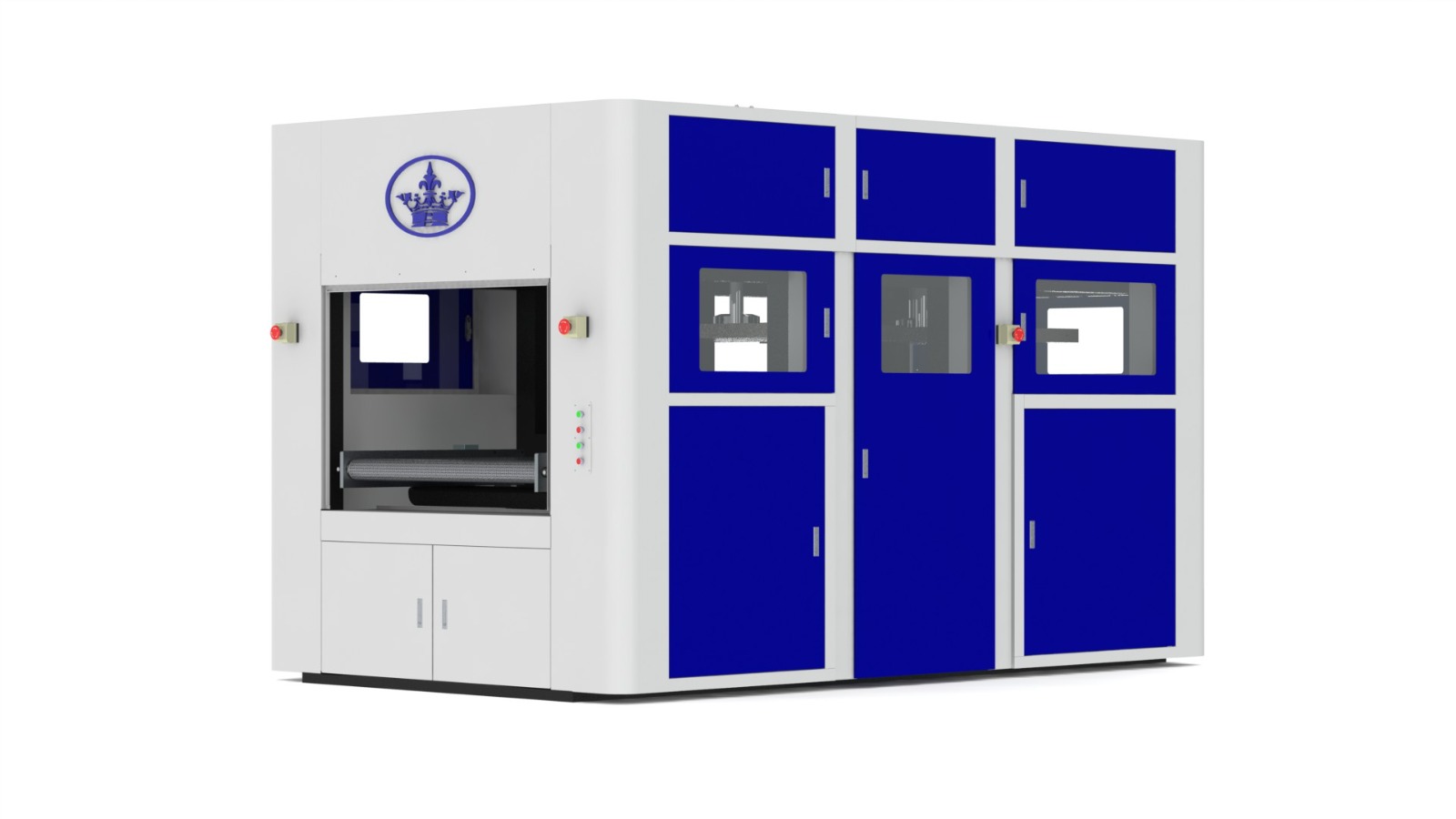

BPMRT - 8012 automatic pulp molded tableware making machine is designed for the purpose of unit molding and shaping, automated production, energy saving and high yield of pulp molding process of products free edge cutting automatic pulping, and environmental friendly hydraulic device and PLC control system.Our PLC System is built with modern technology to control each process system which can be monitored and adjusted with the touchable video screen.

The machine can translate plants fiber sugarcane pulp, bamboo pulp and wood pulp into food packages such as western-style food, dish, bowl, box, supermarket vegetable tray and various beverage cup, coffee cup and more. The packages are suit for microwave oven, oven, frozen, and distillation.

The system can realize setting procedures such as product weight and quality control, automatic remolding, collection and counting, time adjustment of drying and heat shaping, power distribution revision, which make it is able to supply water automatically, feed and mixslurry, form vacuum blank, shape under hot pressing and drying, collect and count of mold unloading. As for the automatic collection device for products, it consists optical fiber alarming device and transfer device for monitoring pulp product transferring and other usage. These devices are connected with computer system, if the fault occurs, it will automatically stop the devices and alarm.

| Item | Specification |

|---|---|

| Machine Model | BPMRT-8012 |

| Mold Size | 800 x 1200mm |

| Production Capacity | Up to 600 KG (Depends upon products specification) |

| Cycle Time | 35-40 Seconds (Depends upon products specification) |

| Weight | Approx. 6 Tons (Excluding Mold) |

| Dimension | L 3614mm/W 2170mm/H 2500mm |

| Machine Body | Ductile Iron |

| Heating | Electric Heating |

| Electric Heating | Multifunctional – Tableware & Industrial Packaging. |

| Control Type | P.L.C |

| Noise | ≤ 85dB |

| Packing | Complete Machine, Crate |

Due to technological innovation, the technical specification can be changed.